The mutually beneficial partnership between OEMs and MROs

During the past 59 years, Duncan Aviation team members have established an excellent rapport and cultivated thousands of relationships.

What's more impressive is the type of relationships they choose to seek out and grow. From other MROs and smaller niche repair shops to original equipment manufacturers (OEMs), the relationships team members at all levels develop help customers and the industry in general.

Establishing a connection with almost every OEM is a priority for Duncan Aviation because those connections lead to a better experience for our mutual customers.

It was important to build those relationships in the 1950s when Founder Donald Duncan was selling aircraft, and it is crucial today as we continue to grow our full-service maintenance, repair and overhaul facilities.

"Some of these relationships, like the ones we have with Beechcraft, Learjet and Cessna, have existed since day one," says Vice President of Sales John Slieter. "On one hand, we may compete on certain projects, but when we work together, it benefits the customer, which is our collective goal."

Duncan Aviation team members work on all the main makes and models of business aircraft, completing STCs, APU installations, engine maintenance, airframe inspections, paint and interior completions and overhauling and replacing parts.

Working with the OEMs has proven to be a viable endeavor for all parties. For example, Duncan Aviation technical representatives, who are employed by Duncan Aviation but who specialize and immerse themselves in the technicalities of specific aircraft makes, currently sit on several OEM advisory committees to assist in the development of their aircraft or engine maintenance programs.

"We divide up our technical representatives by airframe so they can focus on a handful of aircraft and become experts," explains Airframe Maintenance Manager Chad Doehring. "As they build on their experience, they develop relationships. When we need something, our team has relationships with technical experts who work for the OEM involved. We return that favor, and because of that collaboration, the customers win."

Duncan Aviation often works on aircraft that are still under warranty and continues to work on those same aircraft their entire life cycle, until retirement. That experience allows our technicians, mechanics and technical experts to provide OEMs with unique insights.

"I share with Dassault where we can improve the maintenance process and what I'm seeing in the field, because I see aircraft of all ages, operated in a variety of environments," explains Duncan Aviation's Falcon Technical Representative Ron Grose, who has more than 40 years of aviation experience.

Ron reports unpredictable effects of aging he sees on aircraft and advises the OEM where to consider adjusting documents or tasks. Dassault's engineering department and maintenance planning teams take that information, along with reports from other MROs, and use it to improve their maintenance programs, manuals and, ultimately, their products.

How do these relationships start in the first place? Much of the time, they come as a result of a loyal Duncan Aviation customer.

"A lot of these OEM relationships blossom out of a customer request. If we work on a customer's Learjet and he decides to upgrade to a Challenger, he still wants to bring his aircraft to us. That opens the door with the OEM, and we take it from there," says John.

Duncan Aviation's newest partnership is with Gulfstream. All three full-service Duncan Aviation facilities (Battle Creek, Michigan; Lincoln, Nebraska; and Provo, Utah) are now authorized warranty facilities for the G100, G150 and G200 model aircraft.

As a Duncan Aviation technical representative, Brad Kluthe works as a liaison between the two companies.

"I help with troubleshooting and tasks, clarifying processes," Brad explains. "When I'm not working on an aircraft in-house, I'm staying up-to-date on processes, warranty information, parts programs and ensuring we have all the necessary tooling."

He says the transition to authorized warranty facility won't be a huge change, as his team already has a lot of the training and tooling Gulfstream requires.

John says relationships with OEMs ebb and flow, along with the market.

"Business aviation has grown so quickly, it's been difficult for OEMs and MROs to predict when to build and add new facilities. But as demand outpaces capabilities, we work together to help best meet the customers' needs," he says.

Duncan Aviation Chairman Todd Duncan agrees, adding that the relationships between MROs and OEMS help the industry overall.

"We have healthy competition in our industry, and I think it pushes us to always strive for the next best thing. In the end, customers get the best products, the industry is still growing and we at Duncan Aviation are doing what we love—nearly 60 years after we started."

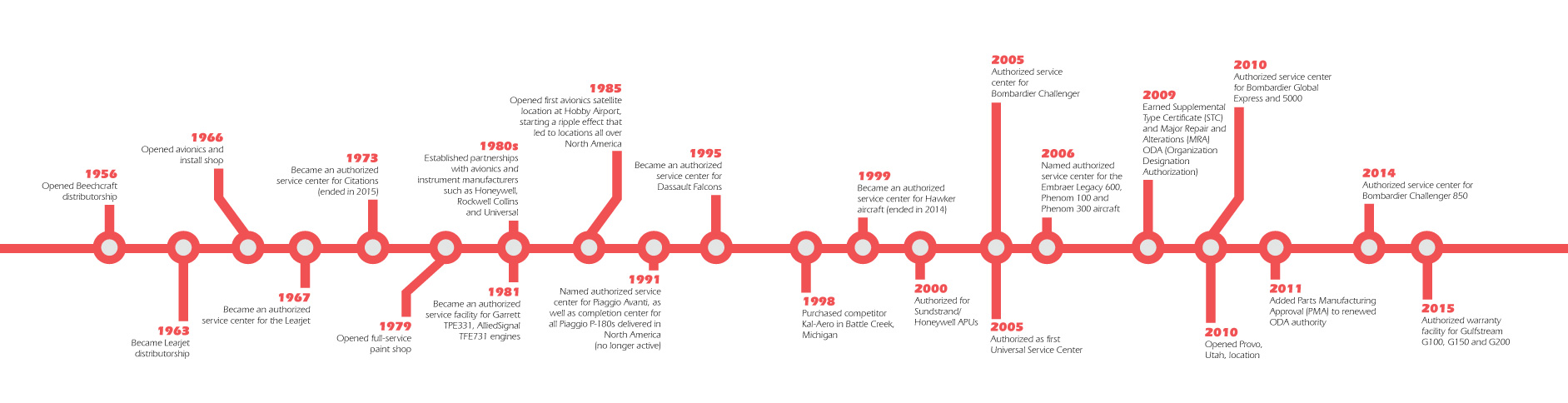

Relationships between original manufacturers and MRO facilities like Duncan Aviation can be complex. The two are often competitors and partners at the same time, but one of the best ways to collaborate in a small industry like aviation is through mutually beneficial projects. The following displays the web of relationships and connections Duncan Aviation has built during the past six decades.