|

| Dry felt with damage to D-ring |

|

| What-is-left-after-dry-felt-is-removed |

|

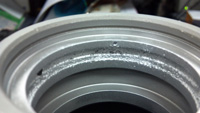

| Corroded-felt-groove-area |

During recent inspections, Duncan Aviation Accessory Technicians have found corrosion on the pistons in the Main Actuator of a Bombardier Learjet 55* aircraft. This area becomes susceptible to corrosion when there is a lack of lubrication on the piston rod felt wiper. Without lubrication, the felt absorbs water and begins to corrode the piston and aluminum housing. If corrosion develops, the piston must be sent out to be re-chromed at a minimum of a six-week downtime or replaced with a new unit. There is no repair for the aluminum housing; it must be replaced.

When the aircraft sits idle, the actuator is fully extended. This is when the shaft should be lubricated. Lubricating the piston rod felt wiper is a Chapter Five item. Refer to the Learjet Maintenance Manual for the proper procedures and frequency. This procedure should be performed on Bombardier Learjet 20, Learjet 30, Learjet 55 and some Learjet 60 model aircraft.

If you have any questions about this, please don’t hesitate to ask.

*Trademarks of Bombardier Inc. or its subsidiaries.

Troubleshooting Classic Learjet Spoileron Systems

Aircraft Sales: Addressing Component Discrepancies During A Pre-Purchase Evaluation

The Critical Role of Lubrication for Aircraft Hydraulic Systems

Five Steps To Extend The Life Of Your Aircraft's Batteries

Preventing Downtime: Tracking Aircraft Wheel Inspections & OEM Limits