Yes, dirt specs should be expected. Your paint service center will provide a guide of the aircraft divided into zones so you know how much debris you should expect.

There are two options to address debris in your aircraft paint: Repaint or sand and polish. If you choose to repaint, there is no guarantee that the area repainted won’t have debris when completed. If you choose to buff, keep in mind some paints are designed to be buffed, but doing so does present some long-term issues related to hazing/staining of the polished areas.

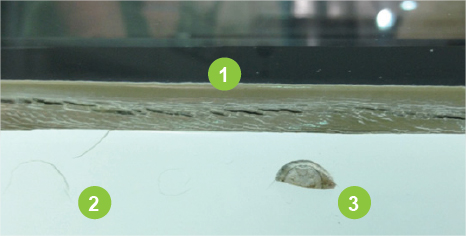

Aircraft are purposely designed to flex and you should expect paint cracks. Sealer seams crack on aircraft due to the expansion and contraction of the aircraft skin. Skin temperatures can range from 130 degrees on the ground  to -50 degrees in the air. The environmental changes cause the expansion of aluminum, composites, sealers and even the paint. When the sealer expands under the surface of the paint, the extra volume causes stress on the paint surface and eventually cracks. And, as an aircraft ages, cracks increase.

to -50 degrees in the air. The environmental changes cause the expansion of aluminum, composites, sealers and even the paint. When the sealer expands under the surface of the paint, the extra volume causes stress on the paint surface and eventually cracks. And, as an aircraft ages, cracks increase.

This photo is of 890 sealant, which was not painted. As you can see, the sealant will crack over time (1). Imagine what would happen if this area was painted. Also, on the bottom left (2) is an example of a rivet cracking and on the bottom right (3) paint has “popped” from a rivet.

August 2024

April 2024

November 2023

June 2022

July 2021