Aircraft aren’t just painted to make them pretty; they’re painted to protect the structure from failure. Every time you fly your aircraft, it’s exposed to environmental elements that will damage the paint over time.

Sun exposure fades paint, wind and sand scratch it, and heat and cold alternately cause the paint to expand and contract – which causes cracking and pitting. Mix in humidity, sea water, air pollution, and ice, and over time, corrosion may start to form, even if only at a microscopic level.

On a metal surface, corrosion needs only oxygen and moisture to get started. Although both elements are necessary for life on earth, they can be detrimental to your aircraft.

Your aircraft also is continually subjected to the normal stresses of flight, including severe temperature and pressure changes. Every component of an aircraft is affected, and eventually, when coupled with corrosion, the structural integrity of the aircraft can be compromised.

View Duncan Aviation Paint Galleries

What can you do to protect your aircraft?

Corrosion can form in different places on or inside the aircraft. Regardless of the type or location of the corrosion, it’s important to have a prevention plan in place. While there is no guarantee that painting your aircraft on a regular basis will prevent all corrosion repairs in the future, if you do not do so, you will be faced with corrosion at some point in the life of your aircraft.

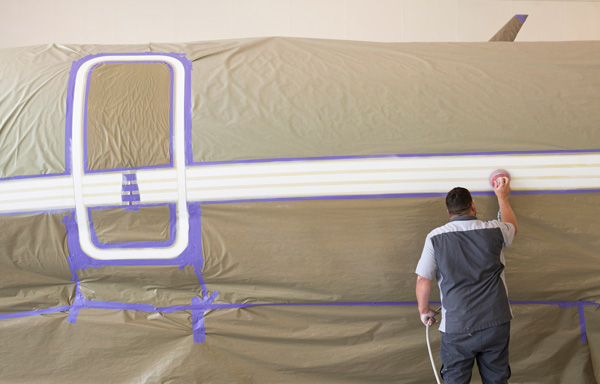

Many owners paint an aircraft thinking how beautiful the stripes and shiny base colors will look. But paying attention to the condition of the paint can pay far larger long-term dividends on the value and safety of the aircraft.

Duncan Aviation 2024 NBAA Maintenance Conference Special Paint Promotion

Duncan Aviation 2024 NBAA Maintenance Conference Special Paint Promotion

We are excited to offer a special 2024 NBAA Maintenance Conference Paint Promotion for a complete exterior strip and repaint for owners and operators of large cabin aircraft. Act now to take advantage of the 10% incentive off the base price for select paint slots at our full-service facility in Provo, Utah, with an input date between May 15th and July 31st of this year. Take advantage of the downtime and get an additional 5% off any interior refurbishment work added to the scheduled paint workscope pending availability.

Each operator who signs up and completes a full exterior paint workscope with Duncan Aviation during the promotion period will receive either a scale aircraft model painted in your livery, or a framed 3D illustration of your aircraft as a gift from Duncan Aviation. Those attending the 2024 NBAA Maintenance Conference in Portland, Oregon, that stop by the booth and schedule their paint project during the conference will be entered for a 1 in 6 chance of winning a Garmin D2 Mach 1 Pro Aviator Smartwatch.

Find a Duncan Aviation Paint and Interior Sales Representative at the NBAA Maintenance Conference to sign up or learn more. The drawing for the watch will be held the first week in July.

Follow this link to find more information about the Duncan Aviation 2024 NBAA Maintenance Conference Special Paint Promotion: https://duncan-dev.dotcms.cloud/services/paint-refurbishment/paint-promo

January 2026

August 2024

November 2023

June 2022

July 2021