When most owners think about what keeps an aircraft airworthy, they picture engines, avionics, landing gear, and flight controls. Rarely does paperwork top the list. Yet no matter how pristine an aircraft is mechanically, incomplete or vague records can ground it faster than a failed component. In aviation, paperwork, especially logbooks, is not administrative busywork; it is a safety-critical, legal record of an aircraft’s life. You may think of it as your own medical records.

Like medical records, logbooks detail the aircraft’s maintenance history from birth. An aircraft’s logbooks are the authoritative history of everything that affects airworthiness: inspections, repairs, modifications, replacements, overhauls, SBs (Service Bulletins), ADs (Airworthiness Directives), and life-limited components. If it isn’t documented, it’s as if it never happened, regardless of whether the work was completed. The result: safety risks, compliance exposure, and avoidable costs.

These gaps in documentation can negatively impact quality assurance and regulatory compliance. Even a perfectly safe aircraft can be deemed unairworthy if you cannot prove its status to the authorities. Logbooks deliver two things that operators cannot afford to lose: safety and legal compliance.

The FAA requires that maintenance and inspections be recorded, but it does not prescribe the level of detail. Since most technicians don’t like to write, that gap often leads to entries such as:

All Chapter 5 requirements complied with at this time.

While technically legal, vague statements create downstream headaches. They leave everyone guessing what was done, when, and by whom. There is no traceability to specific tasks, part serial numbers, or time since new or overhaul. Compliance gaps arise when evaluating ADs, SBs, or OEM program requirements. Finally, there is a risk of rework because shops may require repeat inspections or overhauls to reestablish proof. That means wasted time, wasted money, and unnecessary risk. Clear documentation isn’t just paperwork. It’s protection for your reputation, your operation, and your bottom line.

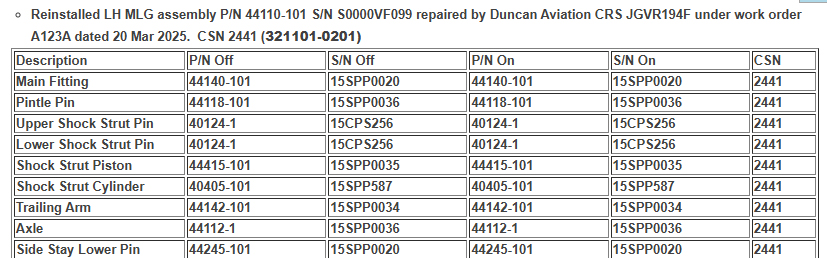

Landing gear logbook entry example from myDuncan

Landing gear logbook entry example from myDuncan

After major inspections or overhauls, vague logbook entries can leave inspectors guessing: What was done? Were Chapter 4 (Airworthiness Limitations) items addressed? How much life remains on critical parts?

This lack of clarity becomes especially problematic for components with limited service life, such as landing gear. Inspectors need to know: Was the part repaired, overhauled, or completely replaced? At installation, was it brand new or previously overhauled? How much usable life remains? If these details aren’t documented, the answers are uncertain, often forcing owners to repeat inspections or overhauls just to prove compliance.

Detailed logbook entries safeguard owners over the long term by reducing confusion, eliminating assumptions, and giving future inspectors confidence in the aircraft’s maintenance history. Adding supporting documentation, such as work order summaries, offers an extra layer of protection. If an entry is challenged years later, these records can provide the evidence needed to prevent unnecessary and costly repeat maintenance. In today’s technical era, it’s much easier to maintain digital copies of detailed records.

Complete, well-documented logbook entries protect the aircraft owner, the maintenance organization, and the technician. They ensure transparency, compliance, and efficiency throughout the aircraft’s lifecycle. Maintenance records aren’t optional. They’re required living documents that determine whether an aircraft can fly today, tomorrow, and in the years ahead. Clear, detailed entries minimize risks, prevent unnecessary expense, protect resale value, and keep you compliant.

February 2026

February 2026

February 2026

February 2026

February 2026