Can I still use my M&TE (measuring and test equipment) when it fails to meet the tolerances set by the manufacturer or my company?

I get this question from time to time. The short answer is yes, but ONLY if you understand how this limitation will affect the task being performed with this tool.

When M&TE fail to meet required tolerances, it can be given a Limited Calibration allowing it to remain in use with reduced capability or functionality.

For Example:

A 6” caliper has a tolerance of ±0.001”. It is indicating 1.0015” when it should be indicating 1.0000”. This M&TE could remain in use with its limited capability if the calibration is limited to ±0.002”.

Let’s continue with the 6” caliper example to show a limitation for reduced functionality. Calipers are capable of measuring OD (outside diameters), ID (inside diameters), and depth. If the OD jaws are within the stated ±0.001” tolerance, but the ID and depth rod are not, we could limit the calipers to “ID Jaws and Depth Rod Not Calibrated.” This allows the calipers to remain in service but only to measure outside dimensions since the OD jaws would be the only part calibrated. The OD jaws are the most commonly used function of the caliper; the ID and depth rod may never be used and therefore do not need to be calibrated.

What Does This Mean?

The examples above allow for the continued use of tools that may otherwise need to be replaced. Before a limited calibration is accepted, you need to understand how that tool is being used and to what tolerance the task is requiring.

When measuring the outside diameter of tubing, you must use calipers with calibrated OD jaws. If the tubing needs to be ± 0.005” and the caliper has a limitation of ± 0.005”, you should be questioning the use of this tool. If the tubing has a tolerance of ± 0.1”, a calibration limitation of ± 0.005” is adequate.

It is your responsibility to understand and ultimately accept calibration limitations to M&TE. The Duncan Aviation Calibration Lab will offer suggestions on a limitation based on the calibration readings, however they do not know how each tool is to be used and whether a limitation would be adverse to the task being performed. Research the impacts of the limitation on a specific task and determine if the limitation will have no adverse impact. Only then should the limitation be accepted.

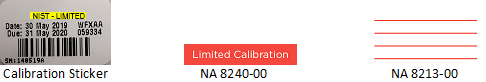

If you accept a calibration limitation the calibration lab will identify the equipment as being limited. The M&TE will have a calibration notation of “NIST – LIMITED” on the top of the calibration sticker. There will be a Limited Calibration sticker (NA 8240-00) with the limitation fully explained on the supplemental limitation sticker (NA 8213-00).

With this information there should be no confusion the equipment is limited and what the limitation is. Only you can determine if this equipment, in its limited state, is the correct tool for the task to be performed.

February 2026

February 2026

February 2026

February 2026

February 2026