Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

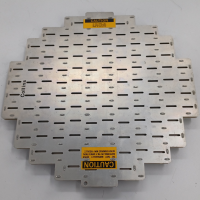

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

Removing the leading edges prior to painting an aircraft will prevent a thick line of paint from building up along the tape lines behind those edges.

The light alloy brackets and levers in the center wheel well area and wing rear spar are susceptible to severe corrosion if the protective coating is compromised and remedial action is not taken promptly.

Recent revisions to the Learjet aircraft Chapter 5 Replacement Schedule now include an upgraded strut with a replacement interval of 16,500 landings.

Don’t overlook inspecting the phenolic bushing in the top mount of the APU exhaust. It is commonly broken or missing.

The Honeywell ART 2000 and ART 2100 are high-performance modern radar that is proven reliable. But even simple things like getting in a hurry when shutting down the system can have a huge negative impact on operation over time.

Because of our long history and experience with the Falcon aircraft, we know the most commonly exchanged parts and keep an inventory available to meet customer needs.

When planning for your Challenger 300 aircraft maintenance event, don’t forget these important Service Bulletins that include the modification of the thrust reverser kicker plate and thrust reverser pivot door forward fitting.

There is a lot of good information online to helpfully troubleshoot a Nose Wheel Steering System the first time, saving significant time and money.

Although Service Bulletin SBF2-12-001 is not mandatory, API strongly recommends compliance during the next maintenance event in which the ailerons are removed from the aircraft.

If you have the centrifugal compressor impeller with the designated part and serial number, accomplish the initial borescope inspection at the next designated airframe inspection.