As an MRO, Duncan Aviation is continually looking for ways to help you keep a sharp eye on your bottom line, reducing costs, increasing reliability, and cutting downtimes. Being able to offer PMA (Parts Manufacturer Approval) replacement parts is one viable solution to all three.

PMA replacement parts are nothing new, but over time have become more widely accepted in the industry. “Using PMA parts just makes good sense,” says Jim Ferguson, Duncan Aviation’s ODA (Organization Designation Authorization) PMA Administrator. “PMA is like a generic prescription. People were skeptical in the beginning, but as costs, quality, and lead times continued to improve, that philosophy changed and is preferred by customers as an alternative and often an improvement over the original.”

Duncan Aviation was granted its first PMA Authority by the FAA more than 35 years ago, allowing us to manufacture aviation-related parts intended for installation on an aircraft. Initial PMA efforts were to support our STC (Supplemental Type Certificate) customers with parts when necessary.

Today, Duncan Aviation has an entire department dedicated to PMA certifications and manufacturing not only to support STCs, but to identify PMA opportunities for some of the most common aircraft parts not readily available.

PMA replacement part numbers can save operators hundreds, if not thousands, of dollars in maintenance costs.

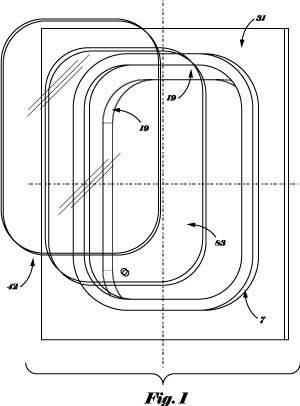

For example, operators of a certain model aircraft can get PMA replacement window dust panes for $100 each, an 86% aftermarket savings. Typically when it comes to dust panes, if you are replacing one, you are replacing them all, which can be 10 to 20 panes per aircraft. As you can see, thousands of dollars can be saved by choosing the PMA option. Not only is there a cost-savings, but there is a time-savings as well; these dust panes are kept in inventory and are available with no lead time.

Many of our PMA replacements are an improvement of the original design because our customers wanted something better, and we listened.

Concerned with how the main cabin curtains hang, bind, and drag along the tracks, some aircraft operators asked us to develop an improved design. Through a lot of trial and experimentation, we manufactured and certified a new PMA roller bearing curtain glide that operates smoothly in the tracks and along the curvature of the aircraft. This improved, popular design is also in stock and available.

Parts availability is always a concern for operators, especially for legacy aircraft. Parts may no longer be available from the manufacturer, or there is an extremely long lead time to get them. This can delay a maintenance event for several weeks, if not months. At Duncan Aviation, we keep an inventory of our PMA replacement parts so they are available when needed.

Chad Ladwig, Duncan Aviation’s PMA Project Lead, is in charge of exploring PMA opportunities throughout the industry. He says there is no shortage of ideas. “I receive ideas from technicians all across the company.”

He works closely with Duncan Aviation’s Engineering and Certifications team, as well as outside resources, turning these ideas into cost- and time-saving alternatives for our customers. Duncan Aviation has engineered more than 980 PMA parts. For a complete list of parts available through Duncan Aviation’s PMA authorization, consult the FAA Regulatory & Guidance Library.

Duncan Aviation holds an ODA from the FAA for STCs, MRAs, and PMAs.

View our PMA Library to find a solution for your aircraft: www.DuncanAviation.aero/pma-library